Fulton RB Horizontal Steam / Hot Water Boiler

Built/Certified in Accordance in to ASME Boiler and Pressure Vessel Code

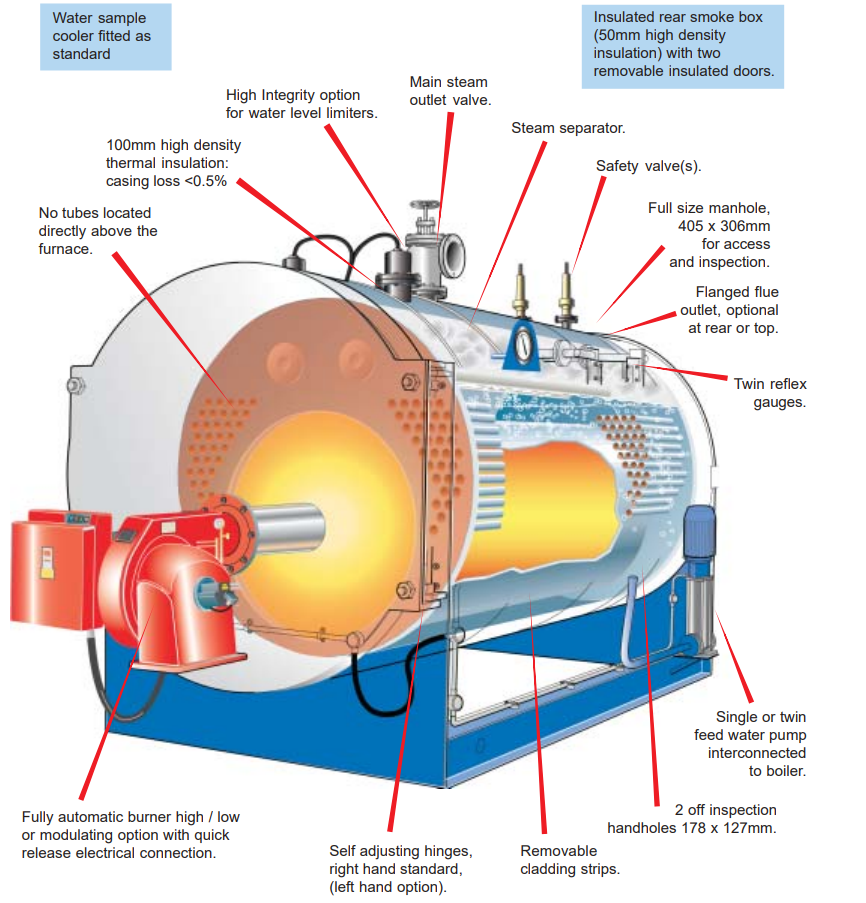

The RB series boiler is a wet-back reverse flame horizontal boiler. With large furnace volume, large furnace surface area, the furnace exit temperature is reduced via enhanced radiation and convection, and front gas chamber condition is much better than the regular reverse fire boilers.

It has a large number of fire tubes and a large tube total cross-sectional area. It’s water level probe directly immerses into pressure vessel, which avoids false water level, and increases operating security.

The RB series boiler is a compact size boiler which can fit in the container.

The concept was to design and manufacture the best horizontal reverse flame, three pass, wet back steam/hot-water boiler on the market

Tailored Solutions for Every Industry: The Fulton Series’ Pledge of Performance and Flexibility

Supported Industries

Robust with Performance

Fulton’s RB Boiler is a high quality horizontal firetube boiler. With more than 10,000 boilers sold in more than 40 countries, the RB has proven itself time and again for customers around the world. All RB boilers are factory packaged with and integrated boiler, burner, and control package configured to provide the industry’s lowest cost of ownership.

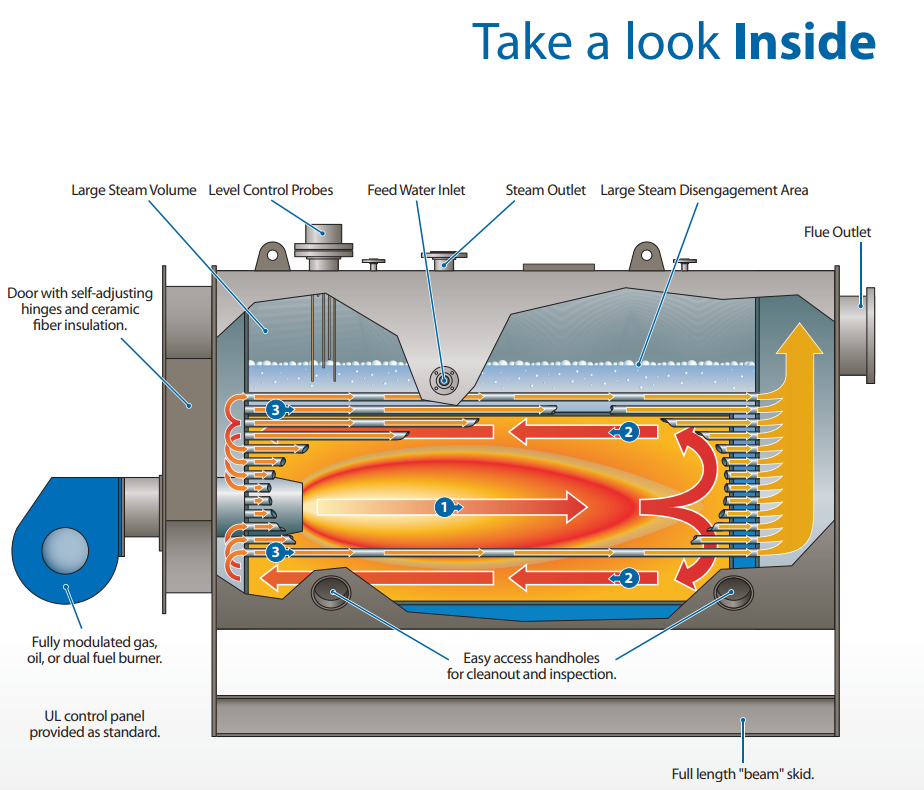

Key Component/Features View of Fulton RB Horizontal Steam / Hot Water Boiler

Design Features:

- Designed and constructed to BS 2790 or ASME code, with standard maximum operating pressure of 1.0 MPa.

- Equipped with Nu-Way (special for RB series with Fulton brand) oil, gas or dual fuel automatic high/low burner, modulating burner is optional according to customer requirement.

- Deviated front door, easy access and inspection of welds, 100% NDT (Non-destructive Test) on all major pressure vessel welds.

- Compact Design, smaller than boiler of equal capacity.

- Water level probe directly immerses into pressure vessel. It avoids false water level, increases operating security.

- High Efficiency

- Large Steam Disengagement Area

- Hinged Door Construction with Integral Burner

- Wet Back Design & Low Skin Losses

- Seamless Heavy Walled Tubing with Turbulators