Fulton FB-A Vertical Steam Boiler

Built/Certified in Accordance in to ASME Boiler and Pressure Vessel Code

The Fulton FB-A Vertical Steam Boiler represents a pinnacle in efficient steam generation. Crafted with precision engineering and cutting-edge technology, the FB-A boiler exemplifies Fulton's commitment to reliability and performance. Its vertical design optimizes space utilization while maintaining superior efficiency, making it ideal for various industrial applications where space is at a premium. With a robust construction and advanced control systems, the FB-A ensures consistent steam production while minimizing energy consumption. Its versatility allows it to adapt to diverse operational needs, providing a reliable source of high-quality steam for heating, sterilization, and other industrial processes. Fulton's FB-A Vertical Steam Boiler stands as a testament to innovation and excellence in steam generation technology.

Unmatched Durability Meets Versatility

Supported Industries

Simple, Reliable, and Efficient

Unlock unparalleled efficiency and reliability with the Fulton FB-A Vertical Steam Boiler. Engineered for excellence, this cutting-edge boiler redefines steam generation, offering a compact yet powerful solution for diverse industrial applications. With its vertical design, the FB-A maximizes space utilization, making it the perfect choice for installations where floor space is at a premium. Crafted with precision engineering and advanced control systems, this boiler delivers consistent steam production while minimizing energy consumption, ensuring optimal performance and cost savings for your operations.

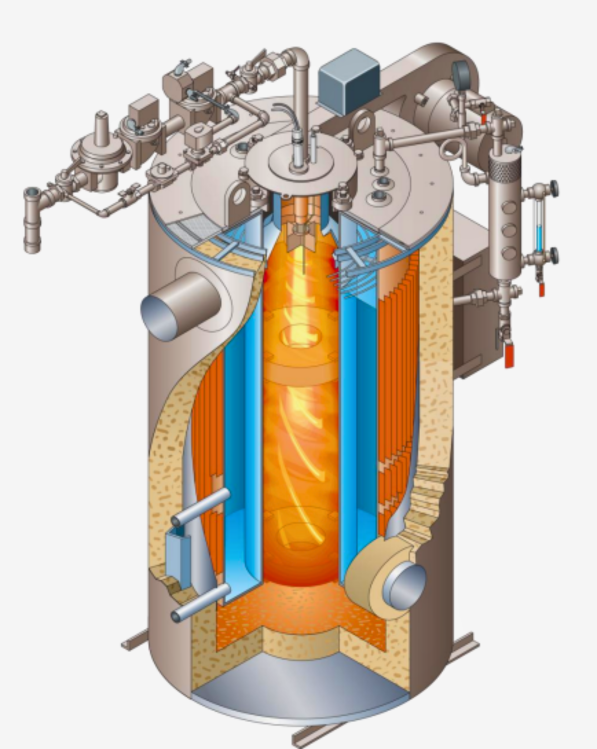

Component View/Features of the vertical tubeless boiler (4-60BHP.)

- 2-pass, Vertical Tubeless

- Small Footprint

- Up to 81% Efficient

- High Temperature Castable Insulation

- Fulton Down-fired Burner

- UL listed as a Packaged Boiler

- Simple, reliable and very forgiving - over 100,000 installed

- Natural Gas/Propane/#2 Oil fuels

- 4HP – 60HP, Section I design boilers only

- Standard firing rate on/off

- Upgrade firing rate to linkage modulation

with 2:1 turndown on natural gas

The Fulton Difference

Fulton FB-A furnace’s unique “pipe within a pipe” structure sets us apart in the industry. The ingeniously top-mounted burner propels a spiraling, cyclonic flame through the central chamber, ensuring a thorough and even distribution of heat. As the hot gases ascend in the secondary flue passage, they interact with strategically placed heat convection fins. These fins expertly transfer residual heat to the water vessel’s exterior, achieving unparalleled uniform heating. This meticulous design not only enhances efficiency but also significantly extends the lifespan of the pressure vessel, embodying our commitment to excellence and durability.

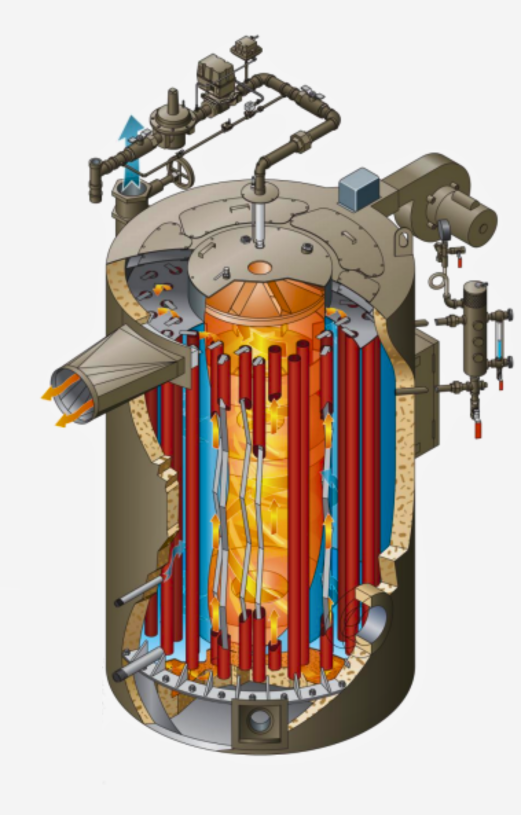

Component View/Features of the VMP Design (80-150BHP.)

- 2-pass, Pipe-Type

- Sch. 80 pipes, not tubes

- Up to 84% efficient

- Preheated combustion air

- Turbulators for higher efficiency

- Small Footprint

- 80HP-150HP

- Section I or Section IV design

- Standard modulation is linkageless with

3:1 turndown on natural gas• Small Footprint

The Fulton Difference

Decades after pioneering the vertical tubeless boiler, Fulton presents the groundbreaking Pipetype Boiler. Built with robust Schedule 80 pipes, this boiler eliminates the need for frequent replacements, offering a lasting solution. Our design, honed over sixty years, comes with a warranty that’s second to none. Experience the Fulton difference firsthand or contact us to examine a physical sample of our superior “Pipe vs. Tube” construction.