Fulton FBL

High Efficiency Electric Steam Boiler

Fulton comprehensive range of electric steam boilers, meticulously crafted to be fully packaged and environmentally conscious, boasting zero NOx emissions. These boilers epitomize durability with their rugged design and come equipped with fully-insulated pressure vessels to minimize radiation losses. Through precise engineering, a meticulously calculated heat-to-steam ratio ensures swift attainment of operating pressures, achieving nearly 100% efficiency in the process.

Great with different industries

Fulton’s commitment to quality and sustainability makes their electric steam boilers an excellent choice for various industrial applications.

Efficient, Quiet, and Safe Operation

Fulton manufactures a comprehensive range of electric steam boilers (FB-L) spanning from 12 kW to 2,000 kW (1.2 to 200 BHP), operating at pressures up to 300 PSI. These boilers are designed for both heating and process applications.

Fulton’s vertical design embodies a fully packaged steam boiler that adheres to ASME specifications and relevant standards. Key features include:

BETTER BY DESIGN

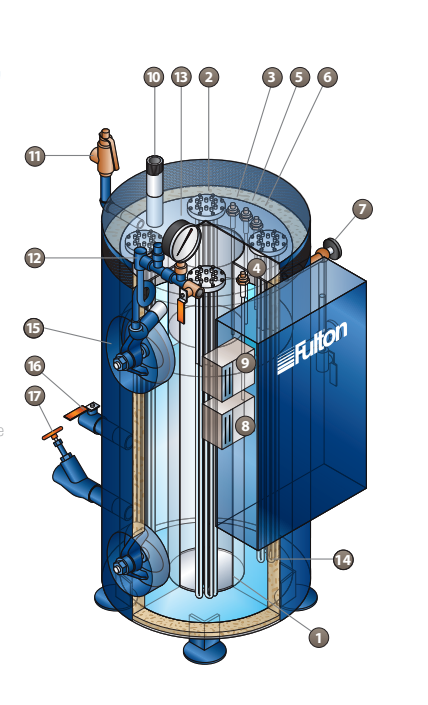

A LOOK INSIDE:

- 1. Pressure Vessel Is Built To ASME Code

- 2. Electric Heating Elements

- 3. Low Water Cut Off Probe

- 4. Auxiliary Low Water Cut Off Probe

- 5. Pump “On” Probe

- 6. Pump “Off” Probe

- 7. Sight Glass Assembly

- 8. Operating Pressure Control

- 9. High Limit Pressure Control

- 10. Steam Outlet

- 11. Safety Valve

- 12. Steam Gauge Assembly

- 13. Steam Pressure Gauge

- 14. High Temp Insulation Surrounds The Vessel

- 15. Large (3” x 4”) Easily Access Handholes

- 16. Feedwater Shut-Off Valve

- 17. Blowdown Valve

| MODEL | 012L | 015L | 018L | 024L | 030L | 036L | 050L | 075L | 100L | 150L | 200L | 300L | 500L | 750L | 1000L | 1250L | 1500L | 1750L | 2000L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SPECIFICATIONS | |||||||||||||||||||

| Unit Size kW | 12 | 15 | 18 | 24 | 30 | 36 | 50 | 75 | 100 | 150 | 200 | 300 | 500 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 |

| HP | 1.2 | 1.5 | 1.8 | 2.4 | 3 | 3.6 | 5 | 7.5 | 10 | 15 | 20 | 30 | 50 | 75 | 100 | 125 | 150 | 175 | 200 |

| Steam Output* LBS/HR | 40 | 50 | 60 | 81 | 101 | 121 | 169 | 252 | 336 | 505 | 674 | 1011 | 1684 | 2526 | 3368 | 4210 | 5052 | 5894 | 6136 |

| Element Count | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 4 | 6 | 4 | 4 | 7 | 10 | 14 | 17 | 20 | 24 | 27 |

| ELECTRICAL | |||||||||||||||||||

| ELECTRICAL, 208V / 3 Phase Amps | 34 | 42 | 50 | 67 | 84 | 100 | 139 | 208 | 278 | 416 | 556 | 832 | 1388 | 2083 | 2777 | 3472 | 4166 | 4861 | 5556 |

| ELECTRICAL, 240V / 3 Phase Amps | 29 | 36 | 43 | 58 | 73 | 87 | 120 | 180 | 241 | 361 | 481 | 724 | 1205 | 1807 | 2409 | 3012 | 3614 | 4217 | 4819 |

| ELECTRICAL, 380V / 3 Phase Amps | 18 | 23 | 27 | 36 | 46 | 55 | 76 | 114 | 152 | 228 | 304 | 456 | 760 | 1140 | 1519 | 1899 | 2279 | 2659 | 3039 |

| DIMENSIONS | |||||||||||||||||||

| DIMENSIONS (A) Boiler Height IN | 24 | 24 | 24 | 24 | 24 | 24 | 55 | 55 | 55 | 55 | 55 | 75 | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

| DIMENSIONS (B) Height w/ Piping IN | 30 | 30 | 30 | 30 | 30 | 30 | 65 | 65 | 65 | 65 | 71 | 80 | 80 | 80 | 80 | 94 | 94 | 94 | 94 |

| DIMENSIONS (C) Width Overall IN | 33 | 33 | 33 | 33 | 33 | 33 | 35 | 42 | 42 | 46 | 52 | 56 | 64 | 72 | 91 | 91 | 99 | 99 | 99 |

| DIMENSIONS (E) Boiler Diameter IN | 20 | 20 | 20 | 20 | 20 | 20 | 17 | 24 | 24 | 28 | 32 | 36 | 44 | 50 | 63 | 63 | 74 | 74 | 74 |